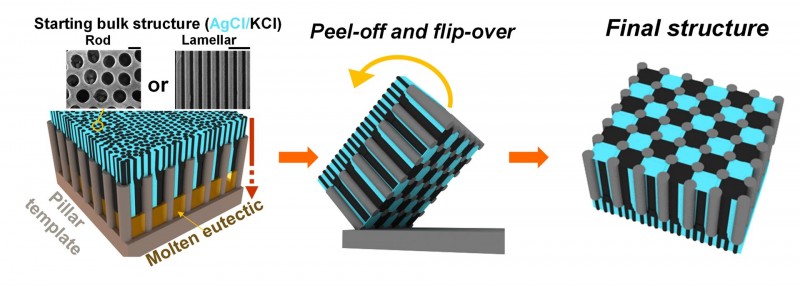

(Nanowerk Information) Self-assembled solidifying eutectic supplies directed by a template with miniature options display distinctive microstructures and patterns on account of diffusion and thermal gradients brought on by the template. Regardless of the template making an attempt to power the fabric to solidify into an everyday sample, when the template carries loads of warmth it can also intrude with the solidification course of and trigger dysfunction within the long-range sample.