A brand new fabrication course of for helical metallic nanoparticles gives a less complicated, cheaper option to quickly produce a cloth important for biomedical and optical units, in line with a examine by College of Michigan researchers.

“One in every of our motivators is to drastically simplify manufacturing of advanced supplies that symbolize bottlenecks in lots of present applied sciences,” mentioned Nicholas Kotov, the Irving Langmuir Distinguished College Professor of Chemical Sciences and Engineering at U-M and co-corresponding writer of the examine, published in Proceedings of the Nationwide Academy of Sciences.

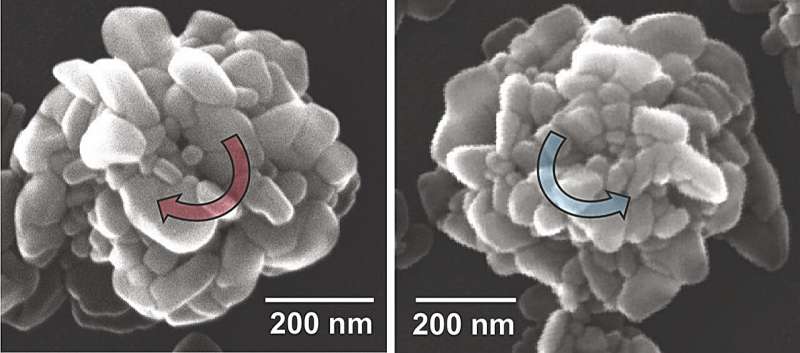

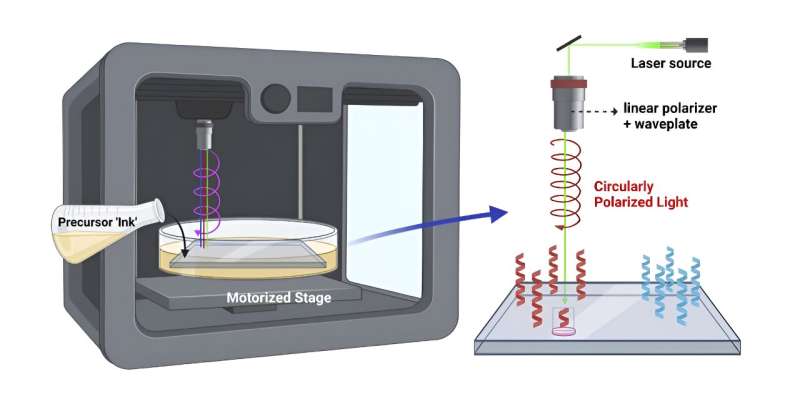

Chiral surfaces—which means the floor lacks mirror symmetry (e.g., a left and right hand)—which have the flexibility to bend mild on the nanoscale are in excessive demand. The brand new examine demonstrates a option to make them by 3D-printing “forests” of nanoscale helices. Aligning the helices’ axes with a light beam creates robust optical rotation, enabling chirality to be harnessed in well being and data applied sciences, for which chirality is frequent.

Chiral surfaces from plasmonic metals are much more fascinating as a result of they will produce a big household of very delicate biodetectors. For instance, they will detect particular biomolecules—produced by harmful drug-resistant bacteria, mutated proteins or DNA—which might help the event of focused therapeutics. These supplies additionally provide potential to advance data applied sciences, creating bigger information storage capacities and quicker processing speeds by harnessing the interplay of sunshine with electronic systems (i.e., fiber optic cables).

Though these particular 3D-structured surfaces from stand-up helices are a lot wanted, the standard strategies to make them are advanced, costly and create quite a lot of waste.

Mostly these supplies are made utilizing extremely specialised {hardware}—similar to two-photon 3D lithography or ion/electron-beam-induced deposition—solely out there in just a few high-end amenities. Though correct, these strategies contain time-consuming, multi-step processing at low strain or excessive temperature situations.

3D printing has been urged as a substitute, however current 3D printing applied sciences don’t permit nanoscale decision. As an answer, the U-M analysis workforce developed a technique that makes use of helical mild beams to provide nanoscale helices with particular handedness and pitch.

“Centimeter-scale chiral plasmonic surfaces might be produced inside minutes utilizing cheap medium-power lasers. It was superb to see how briskly these helical forests develop,” mentioned Kotov.

The 3D printing of helical constructions by helical mild is predicated on the light-to-matter chirality transfer found at U-M about 10 years in the past.

Single-step, mask-free, direct-write printing from aqueous options of silver salt gives an alternative choice to nanolithography whereas advancing 3D additive manufacturing. The processing simplicity, excessive polarization rotation and fantastic spatial decision of light-driven printing of helices from metallic will drastically speed up the preparation of advanced nanoscale structure for the subsequent technology of optical chips.

Extra data:

Ji-Younger Kim et al, Direct-write 3D printing of plasmonic nanohelicoids by circularly polarized mild, Proceedings of the Nationwide Academy of Sciences (2024). DOI: 10.1073/pnas.2312082121

Quotation:

A easy, scalable technique utilizing mild to 3D print helical nanostructures (2024, March 18)

retrieved 18 March 2024

from https://phys.org/information/2024-03-simple-scalable-method-3d-helical.html

This doc is topic to copyright. Aside from any truthful dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is offered for data functions solely.