A world collaboration between EPFL and the College of Glasgow has led to a complicated machine-learning algorithm to successfully detect hid manufacturing defects in wind turbine composite blades—earlier than generators are put into service.

Defective wind turbine blades can incur enormous prices for the businesses that function them, particularly if the defects go unnoticed till it is too late. That is why quality assurance is such a strategic subject for international wind turbine producers. At this time, high quality inspections are restricted to floor inspection of restricted areas as these composite constructions roll off the manufacturing line.

However beneath a brand new strategy co-created by EPFL and College of Glasgow researchers, inspection engineers can use a brand new patented radar expertise, mixed with an AI assistant, to detect potential anomalies beneath the floor. This strategy has many benefits: it is non-destructive, non-contact, helps agile and speedy information acquisition and evaluation, and requires little or no energy to function. The research has simply been printed in Mechanical Techniques and Sign Processing.

Merging sign processing and AI

The analysis attracts on earlier work from each institutional companions. This work was led by Olga Fink, in the present day a tenure-track assistant professor of civil engineering and head of the Clever Upkeep and Operations Techniques Laboratory (IMOS) inside EPFL’s College of Structure, Civil and Environmental Engineering (ENAC).

In earlier analysis, she has developed strategies for detecting anomalies by processing the sounds produced by defective machines, for background noise suppression on audio recordings and for classifying chook songs by infusing studying capabilities into well-known and well-grounded signal processing approaches.

“Producers are constructing wind generators larger, with extra difficult designs. All that will increase the probabilities of a defect occurring in the course of the manufacturing stage,” says Olga Fink, head of the Clever Upkeep and Operations Techniques Laboratory (IMOS).

At this time, she’s new purposes for her AI-driven techniques. “Wind generators are constructed from a number of totally different composite supplies like fiberglass and carbon fiber,” she says. “Producers are additionally constructing them larger, with extra difficult designs. All that will increase the probabilities of a defect occurring in the course of the manufacturing stage.”

Measurement expertise

The College of Glasgow group, led by Prof. David Flynn, James Watt College of Engineering, and Head of Analysis Division for Autonomous Techniques and Connectivity has pioneered strategies in prognostics and well being administration. They’ve explored how Robotics and Synthetic Intelligence (RAI) can assist internet zero infrastructure.

The researchers in Glasgow used a patented Frequency Modulated Steady Wave radar with a robotic arm to examine industrial wind-turbine blade samples at distances of 5, 10 and 15 centimeters from the pattern. Utilizing sign processing strategies, they might isolate options and precursors to future failures in these advanced composite samples (see under a video produced by the College of Glasgow).

Enhancing information illustration

When offering this experimental data to the IMOS group, the problem was to reinforce the data content material of the options embedded inside this uncooked information. It turned out that the alerts obtained by the radar various relying on the inspection distance and the blade’s floor materials and core materials.

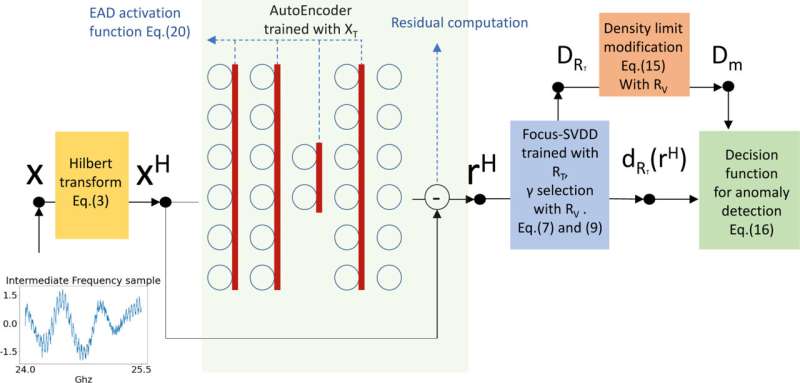

Gaëtan Frusque, a postdoc at IMOS and the research’s lead writer, explains, “At IMOS, we used a complex-value illustration of the alerts to raised separate the data they comprise, and to adapt the AI mannequin accordingly.” In consequence, the algorithm they developed can distinguish anomalies from uniform turbine elements.

The Glasgow researchers now plan to gather extra information to additional validate the IMOS outcomes. The researchers plan to finally take a look at their technique on present generators, which they will do by becoming the sensor to a robotic arm or onto a drone. This could allow them to identify manufacturing defects in generators earlier than they’re put into service or to examine the generators throughout operation. As soon as put in, defect-free generators can function for round 20 years.

Extra data:

Gaëtan Frusque et al, Non-contact sensing for anomaly detection in wind turbine blades: A spotlight-SVDD with complex-valued auto-encoder strategy, Mechanical Techniques and Sign Processing (2023). DOI: 10.1016/j.ymssp.2023.111022

Quotation:

AI-driven technique helps enhance high quality assurance for wind generators (2024, February 22)

retrieved 23 February 2024

from https://techxplore.com/information/2024-02-ai-driven-method-quality-turbines.html

This doc is topic to copyright. Aside from any truthful dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is offered for data functions solely.