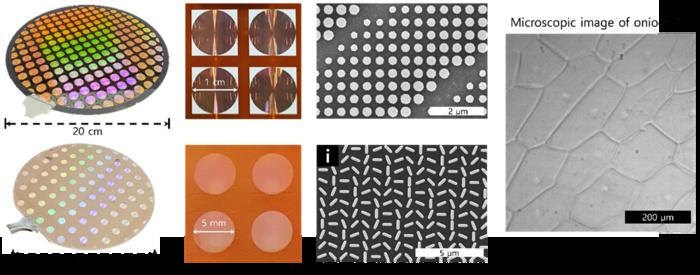

(Nanowerk Information) Metalenses, nano-artificial constructions able to manipulating mild, supply a expertise that may considerably cut back the scale and thickness of conventional optical parts. Notably efficient within the near-infrared area, this expertise holds nice promise for varied functions comparable to LiDAR which is known as the ‘eyes of the self-driving automobile’, miniature drones, and blood vessel detectors.