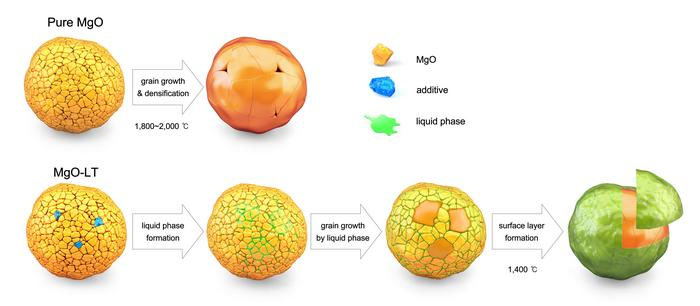

(Nanowerk Information) Dr. Cheol-Woo Ahn, main a analysis workforce on the Division of Purposeful Ceramics throughout the Ceramic Supplies Division on the Korea Institute of Supplies Science(KIMS), has developed the world’s first warmth dissipation materials. This materials reduces hydrophilicity by means of a chemical response that kinds a nanocrystalline composite layer and will increase thermal conductivity by controlling level defects. This course of happens throughout a easy sintering course of that doesn’t require floor therapy.