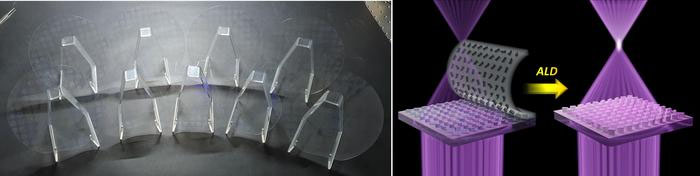

(Nanowerk Information) Ultraviolet rays discover various functions in medical and healthcare, serving functions reminiscent of disinfection, sterilization, and remedy. They’re additionally used within the semiconductor trade for creating microcircuits and patterns. A metalens fabrication course of, developed by a crew of researchers at Pohang College of Science and Technology (POSTECH), permits management over the optical properties of those UV rays. This innovation has garnered vital consideration throughout industries, sparking curiosity in potential developments.