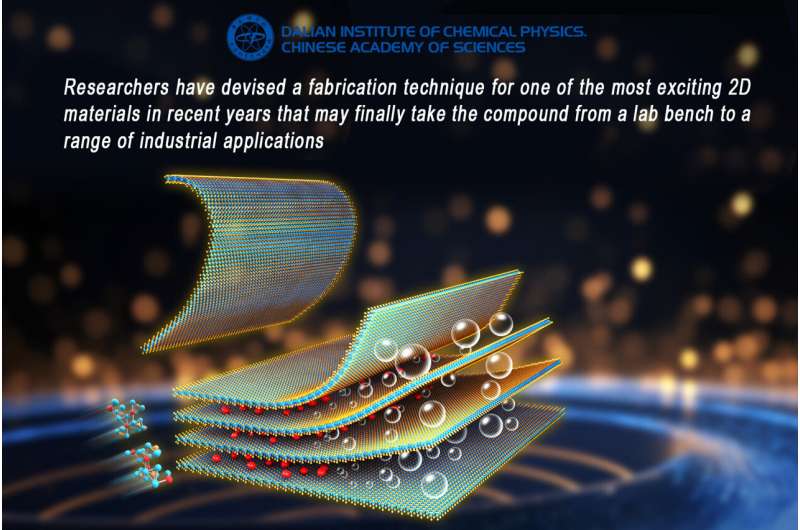

Transition steel telluride nanosheets have proven huge promise for elementary analysis and different functions throughout a rainbow of various fields, however till now, mass fabrication has been inconceivable, leaving the fabric as one thing of a laboratory curiosity somewhat than an industrial actuality.

However a staff of researchers has just lately developed a novel fabrication technique—using chemical options to peel off skinny layers from their guardian compounds, creating atomically skinny sheets—that appears set to ship on the ultra-thin substance’s promise lastly.

The researchers describe their fabrication approach in a research published in Nature.

On this planet of ultra-thin or ‘two-dimensional’ supplies—these containing only a single layer of atoms—transition steel telluride (TMT) nanosheets have, lately, precipitated nice pleasure amongst chemists and supplies scientists for his or her notably uncommon properties.

These compounds, made from tellurium and any of the weather within the ‘center’ of the periodic desk (teams 3-12), get pleasure from a spread of states from semi-metallic to semiconducting, insulating, and superconducting and much more unique states, in addition to magnetic and distinctive catalytic exercise.

These properties supply a spread of potential functions throughout electronics, vitality storage, catalysis, and sensing. Particularly, TMT nanosheets are being explored as novel electrode supplies in batteries and supercapacitors—important for the clear transition—because of their excessive conductivity and enormous floor space.

TMT nanosheets will also be used as electrocatalysts for lithium-oxygen batteries, bettering their effectivity and efficiency. Different potential functions in rising applied sciences embrace photovoltaics and thermoelectrics, hydrogen production, and filtration and separation. They’ve even been discovered to show attention-grabbing quantum phenomena, akin to quantum oscillations and large magnetoresistance.

“The checklist of industries that will get pleasure from vital effectivity enhancements from the mass manufacturing of TMT nanosheets is extraordinarily lengthy,” mentioned staff chief WU Zhong-Shuai, a chemist with the Dalian Institute of Chemical Physics (DICP), Chinese language Academy of Sciences. “For this reason this 2D materials is doubtlessly so thrilling.”

Sadly, regardless of varied makes an attempt at exfoliation of high-quality TMT nanosheets, preserving excessive crystallinity whereas reaching massive nanosheet dimension and ultrathin characteristic continues to be a big problem. The strategies devised to this point are usually not scalable because of lengthy processing instances. Additionally they typically require poisonous chemical substances. Thus, the properties of TMT nanosheets have remained an attention-grabbing laboratory phenomenon that can’t fairly make the leap to mass manufacturing and industrial utility.

The staff lastly cracked this downside through a simplified means of lithiation, hydrolysis and eventually, the nanosheet exfoliation.

First, a bulk amount of steel telluride crystals was ready utilizing chemical vapor transport—a way generally utilized in chemistry to move stable compounds from one location to a different utilizing a service gasoline. When the response vessel is heated, the transporting agent vaporizes and carries the stable compound with it as a vapor.

The vapor travels by the response vessel and will encounter a cooler floor, the place the compound can deposit and kind crystals. This permits for the managed progress of crystals or very skinny movies of the specified compound. On this case, the ready telluride crystals are then combined with lithium borohydride. This course of entails the putting of lithium ions in between the layers of the steel telluride crystals, resulting in the formation of an intermediate, ‘lithiated’ compound.

The lithiated intermediate compound is then quickly drenched with water, which leads to “exfoliation,” or stripping of the lithiated steel telluride crystals into nanosheets in seconds.

Lastly, the exfoliated steel telluride nanosheets are collected and characterised primarily based on their form and dimension, permitting them to be additional processed into totally different varieties, akin to movies, inks, and composites, relying on the specified utility.

The entire course of takes simply ten minutes for the lithiation and seconds for the hydrolysis. The approach is able to producing high-quality TMT nanosheets of various desired thicknesses with very excessive yields.

When testing the nanosheets, the researchers discovered that their cost storage, high-rate capability, and stability made them promising for functions in lithium batteries and micro-supercapacitors.

They consider that their approach is basically prepared for commercialization, however in addition they need to conduct additional research to characterize the properties and habits of their nanosheets, in addition to additional refine and optimize the lithiation and exfoliation levels.

Extra info:

Hui-Ming Cheng, Steel telluride nanosheets by scalable stable lithiation and exfoliation, Nature (2024). DOI: 10.1038/s41586-024-07209-2. www.nature.com/articles/s41586-024-07209-2

Offered by

Chinese Academy of Sciences

Quotation:

Novel fabrication approach takes transition steel telluride nanosheets from lab to mass manufacturing (2024, April 3)

retrieved 3 April 2024

from https://phys.org/information/2024-04-fabrication-technique-transition-metal-telluride.html

This doc is topic to copyright. Aside from any honest dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for info functions solely.