Researchers on the Indian Institute of Science (IISc) have developed versatile movies that exhibit shiny colours purely by advantage of their bodily construction, with out the necessity for any pigment. When stretched, the movies exhibit a change in colour as a response to the mechanical deformation.

To design these movies, the crew devised a novel cost-effective and scalable single-step approach that entails evaporating gallium steel to type nano-sized particles on a flexible substrate. Their methodology permits the simultaneous fabrication of a number of structural colours attentive to mechanical stimuli.

The crew has additionally proven how these movies can be utilized for quite a lot of functions, from good bandages and motion sensors to reflective shows.

“That is the primary time {that a} liquid steel like gallium has been used for photonics,” says Tapajyoti Das Gupta, Assistant Professor within the Division of Instrumentation and Utilized Physics (IAP), and corresponding creator of the examine published in Nature Nanotechnology.

Some pure objects like gems, mollusk shells or peacock feathers are inherently colourful. Their colours emerge from the interplay of sunshine with micro- or nano-structures organized periodically, corresponding to tiny silica spheres in opal, calcium carbonate-based platelets in mollusk shells, and segmented ribbons atop cylindrical buildings in peacock feathers.

Nature-inspired structurally coloured supplies have discovered broad functions in shows, wearable electronics, visible sensors, and anti-counterfeiting tags. Lately, scientists have been attempting to design supplies that may change colour in response to an exterior mechanical stimulus.

The IISc crew started experimenting with gallium, which has not been explored for such functions as a result of its excessive floor pressure hinders the formation of nanoparticles. Gallium is a liquid metal at room temperature and its nanoparticles have been proven to have sturdy interactions with electromagnetic radiation.

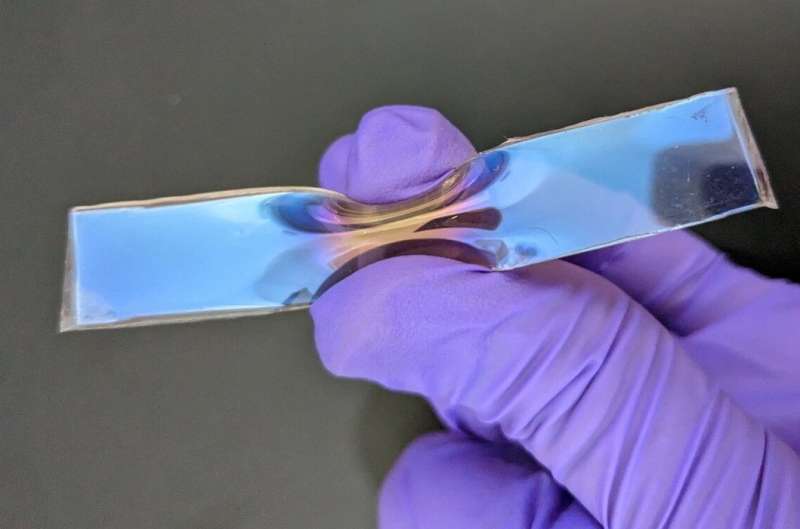

The method developed by the crew achieves the feat of overcoming the barrier of floor pressure to create gallium nanoparticles, by cleverly utilizing the properties of a substrate referred to as polydimethylsiloxane (PDMS), a biocompatible polymer.

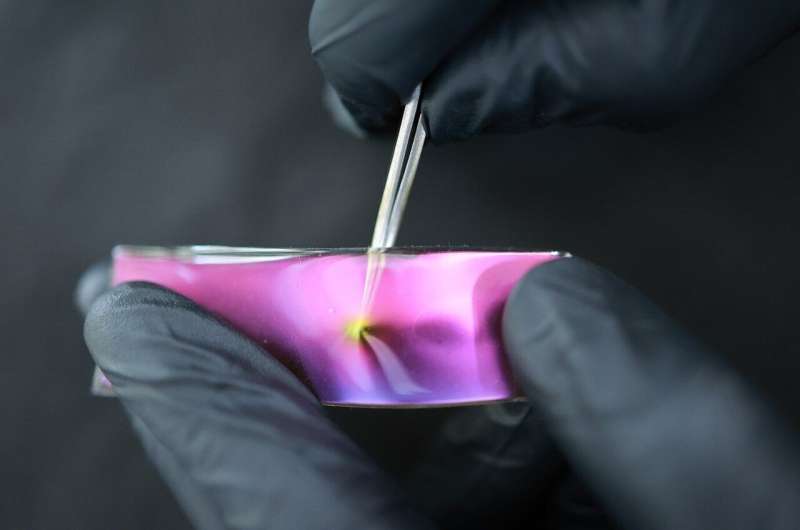

When the substrate was stretched, the researchers seen one thing uncommon. The fabric began exhibiting completely different colours relying on the pressure. The researchers theorized that the array of deposited gallium nanoparticles interacts with mild in particular methods to generate the colours.

To grasp the function of the substrate in colour technology, the crew developed a mathematical mannequin.

PDMS is a polymer made by mixing two liquid-like parts—an oligomer and a cross-linker—which react with one another to type a stable polymer. What the researchers discovered is that the unreacted portion of oligomer, which remains to be in a liquid state, performed an important function in stabilizing the formation of gallium nanoparticles on the substrate.

When this substrate is then stretched, the liquid-like oligomers seep into the gaps between the nanoparticles, altering the hole measurement and their interplay with mild, ensuing within the noticed change in coloration. Experiments carried out within the lab confirmed the mannequin’s predictions. By tuning the ratio of the oligomer content material to the cross-linker, the researchers obtained a gamut of colours.

“We present that the PDMS substrate not solely holds the construction, but additionally performs an lively function in figuring out the construction of gallium nanoparticles and ensuing coloration,” says Renu Raman Sahu, Ph.D. scholar in IAP and lead creator. Even after 80,000 cycles of stretching, the fabric was capable of present a repeatable colour change, indicating its reliability.

Standard methods corresponding to lithography used to manufacture such supplies contain many steps and are pricey to scale up. To avoid this, the crew devised a single-step bodily vapor deposition approach to evaporate the liquid gallium steel and deposit it on the PDMS substrate. This allowed them to manufacture versatile, structurally coloured movies measuring about half the dimensions of a palm.

There are numerous functions potential for such movies. The crew demonstrated one such software: a physique motion sensor. A strip of the movie, when hooked up to the finger, modified colour when the finger was bent, serving to to sense motion in actual time.

Sahu says, “Sooner or later, these supplies might be used for power harvesting functions as nicely.”

Extra data:

Renu Raman Sahu et al, Single-step fabrication of liquid gallium nanoparticles through capillary interplay for dynamic structural colors, Nature Nanotechnology (2024). DOI: 10.1038/s41565-024-01625-1

Sahu RR, Das Gupta T, Fabrication of mechanochromic gallium nanostructures by capillary interactions, Nature Nanotechnology (2024). DOI: 10.1038/s41565-024-01630-4

Supplied by

Indian Institute of Science

Quotation:

Scientists develop tunable coloured movies for shows and sensors (2024, March 19)

retrieved 20 March 2024

from https://phys.org/information/2024-03-scientists-tunable-displays-sensors.html

This doc is topic to copyright. Other than any honest dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is offered for data functions solely.